What are EPs sandwich panels? How is it made? Is it expensive?

18 Feb 2025

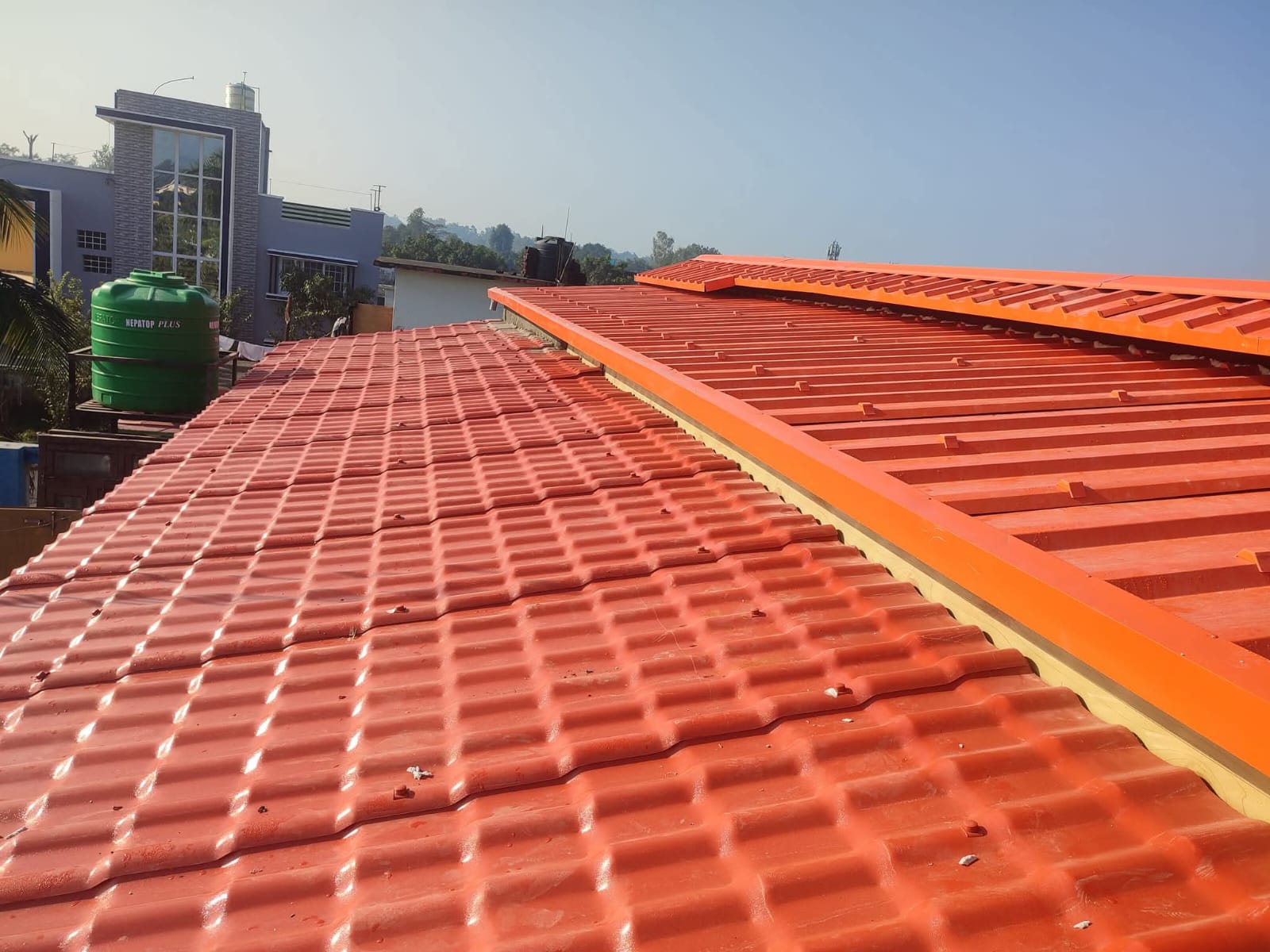

EPS sandwich panels are modern building materials made from Expanded Polystyrene (EPS) foam placed between two strong outer layers—usually made of color-coated steel sheets or fiber cement boards. Think of it like a sandwich: the soft foam is the filling, and the hard layers are the bread.

These panels are lightweight, insulated, strong, and easy to install, making them a popular choice in prefabricated buildings, modular homes, warehouses, cold storage, and even office cabins.

It is maded from small beads of polystyrene which are heated and expanded to form a lightweight, thermal-insulated foam. This EPS foam becomes the core of the panel. Two rigid and durable sheets (commonly galvanized/color-coated steel) are selected. These sheets give the panel mechanical strength and protection from weather, corrosion, and impact. The foam core is bonded between the outer layers using high-strength adhesives or heat lamination.

EPS sandwich panels come with many practical advantages, especially for modern and fast construction such as Thermal Insulation, Lightweight Yet Strong, Quick Construction, Cost-Effective, Water & Moisture Resistant & Customizable & Versatile.